WPC Treatment Service

What is WPC?

WPC is a proven process that has been utilized for many years in the racing and automotive industry. WPC is not a coating, it is a treatment that enhances the surface to reduce friction and strengthen engine parts.

Why is WPC Superior?

The WPC process is unrivalled in treating engine parts and other surfaces that have contact points of friction. WPC is superior because it is not a coating; it is a permanent surface treatment that reduces friction while strengthening the part. It's unique micro-dimple formation pattern greatly reduces friction and is unmatched by conventional methods of surface treatment.

WPC has the capacity to treat carburized, nitrided and plated parts without noticeable dimensional changes, and, upon completion of treatment, no further modifications are required of the parts. The strength and durability improvement on the surface after the WPC treatment is unsurpassed by any current methods.

Treatable products include steel, aluminum, titanium, copper and brass and soft surfaced bearings. WPC can treat any metallic item in a disassembled state.

Reduced Friction

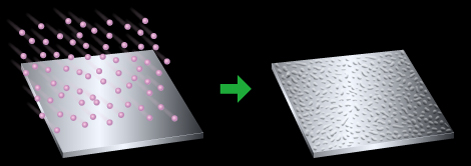

The fine grooves, that are intrinsically engraved into the product surface at the time of machining, are transformed into micro-dimple indentations by the impact of the ultra-fine media during WPC treatment. These dimples then act as oil reservoirs.

Thus, oil that would normally drain away, through the grooves in an untreated product, when pressure is applied, is instead retained in the dimples of a WPC treated product. This helps to keep the surface lubricated.

Furthermore, solid lubricants such as Tin (Sn) and Molybdenum Disulfide (MoS2) can be utilized as media in the WPC process to embed them into the product surface. This reduces friction and improves the life and efficiency of the product to an even greater level. This process is called PIP(Powder Impact Plating).

Greater Durability

The ultra-fine media of the WPC process, when projected at high velocity towards the product surface, creates compressive stress at the impact points. At the same time, a micro thermal reaction takes place. It effectively seals minor surface fractures. It also allows a condensed surface to form that has improved density due to compaction. This altered and highly compact surface condition overcomes the problem of brittleness, that is usually encountered when metals are hardened.

The numerous impacts during the WPC process not only increase the residual compressive stress but also cause it to reside a lot closer to the surface. The cumulative result is a product that has a durability unrivalled by conventional peening methods.

Video Explanation

Leave a comment